Development of Dispensing System for Microdrops Generation in Microarray Applications

The research aims of this project are:

(1) Development of a piezo-actuated dispensing system for microdrops generation with real-time closed loop pressure control to generate droplets with very high accuracy (up to several picoliters) in order to achieve very high-density microarray printing capability.

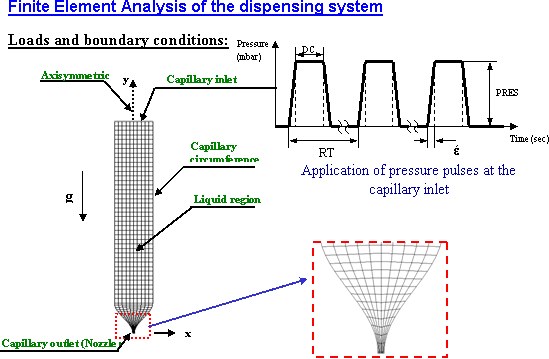

(2) Finite Element Modeling and Analysis using ANSYS for design optimization and performance assessment of the system and mathematical modeling and simulations using Matlab and Simulink.

(3) Development of control techniques using LabVIEW to achieve high accuracy and high throughput dispensing.

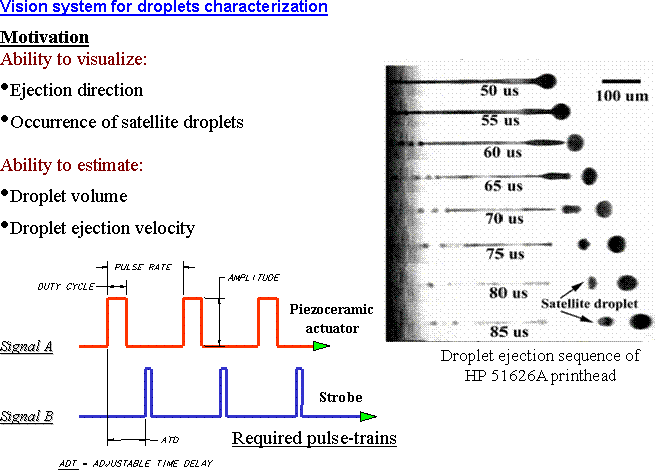

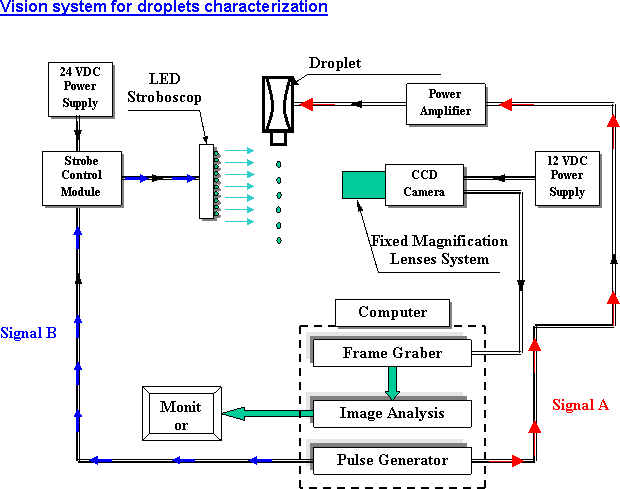

(4) Integration of a vision-based testing equipment to experimentally assess the accuracy and repeatability of the microdroplet generator and to calibrate it.

The diagnostic and pharmaceutical industries are seeking for improved methods of reagent dispensing that would enable them to reduce the amount of reagent used, improve the accuracy and repeatability of the quantities dispensed, and generally expedite the processing of assays and biochips. The forces driving the search for improved dispensing technologies include the need to increase the amount of diagnostic information that can be derived from a patient sample, and a generalized market pressure to reduce the cost of assays.

This research involved the development of a piezo-actuated micro-dispensing system for microdrops generation with real-time closed-loop pressure control to achieve very high density microarray printing capability. The system is operated in a drop-on-demand mode using a non-contact liquid transfer method. This system can be used for DNA (deoxyribonucleic acid) and protein printing applications and production of biochips. The system includes the abilities to handle a wide range of solvents and solutes; to dispense reagents in drop volumes in the range of microliters to picoliters; to achieve very high-density microarray printing capabilities; to introduce a great deal of functionality and control to the dispensing process; to execute various dispensing operations in an automatic mode without manual handling; and to increase throughput by using non-contact dispensing methods.

The work involves the following major steps: (i) Design, analysis and development of prototypes of the precision dispensers; (ii) Development of control techniques to achieve high accuracy and high throughput dispensing; (iii) Integration of multiple dispensers into one functional system capable of producing high-density biochips; (iv) Development and integration of vision based testing equipment to experimentally assess the accuracy and repeatability of the dispensers and to calibrate them.

The dispenser array to be developed, the control modules and the vision based assessment and calibration technique are expected to lead to a platform of technologies for the production of biochips required in various medical, pharmaceutical and biotesting applications. This platform will allow the production of high-density biochips. Such density is not achievable with any of the systems currently available commercially or under development.