Wireless Hybrid Mobile Robot System: Interchanging and Adaptive Locomotion and Manipulation

The research aims of this project are as follows:

(1) Development of novel design paradigm of a hybrid mobile robot system with compounded locomotion and manipulation capability in order to enhance robot mobility and maximize functionality in field operations.

(2) Optimization of the mechanical design of the hybrid robotic system through dynamic simulations using ADAMS and mathematical modeling.

(3) Development and implementation of novel on-board wireless real-time sensor/actuator control interfaces for the hybrid mobile robot.

(4) Construction and integration of a prototype of the hybrid mobile robot system including the development of a computer architecture and control system design.

(5) Experimental setup, testing and calibrations of the integrated system.

The use of mobile robots is growing very rapidly in numerous applications such as planetary exploration, police operations (e.g., EOD - Explosive Ordnance Disposal), military operations (e.g., reconnaissance missions, surveillance, neutralization of IED), hazardous site exploration, and more. The use of Unmanned Ground Vehicles (UGVs) in Urban Search and Rescue (USAR) and Military Operations on Urbanized Terrain (MOUT) is gaining popularity because the mobile robots can be sent ahead or in place of humans, act on the surroundings with a manipulator arm or other active means attached to an arm, collect data about its surroundings, and send it back to the operator with no risks posed to humans.

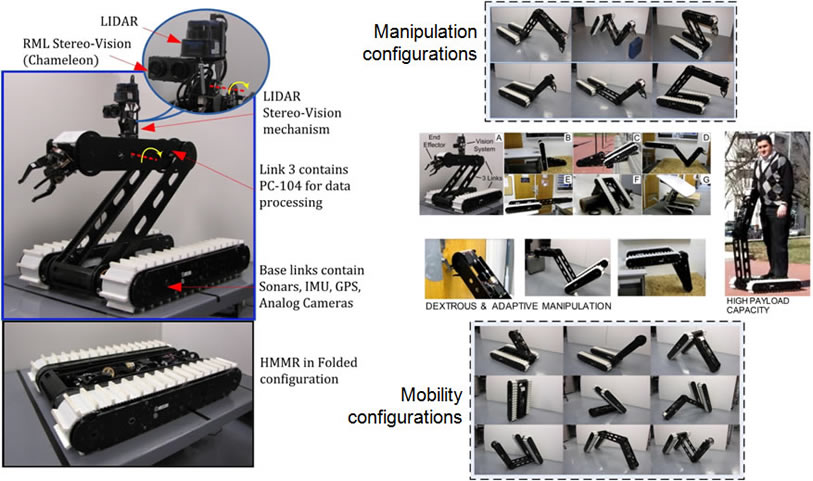

This research presents a novel design paradigm of mobile robots: the Hybrid Mobile Robot system. It consists of a combination of parallel and serially connected links resulting in a hybrid mechanism that includes a mobile robot platform for locomotion and a manipulator arm for manipulation, both interchangeable functionally. This robot enhanced functionality is further complemented by an interchangeable track tension and suspension mechanism that is embedded in some of the mobile robot links to provide the locomotion subsystem of the robot.

All state-of-the-art mobile robots have a separate manipulator arm module attached on top of the mobile platform. The platform provides mobility and the arm provides manipulation. Unlike them, the new design has the ability to interchangeably provide locomotion and manipulation capability, both simultaneously. This was accomplished by integrating the locomotion platform and the manipulator arm as one entity rather than two separate and attached modules. The manipulator arm can be used as part of the locomotion platform and vice versa. This paradigm significantly enhances mobile robot locomotion and manipulation functionality for the aforementioned applications.

The new mechanical design was analyzed with a virtual prototype that was developed with MSC Adams Software. Simulations were used to study the robot's enhanced mobility through animations of challenging tasks. Moreover, the simulations were used to select nominal robot parameters that would maximize the arm's payload capacity, and provide for locomotion over unstructured terrains and obstacles, such as stairs, ditches and ramps.

The hybrid mobile robot also includes a new control architecture based on embedded on-board wireless communication network between the robot's links and modules such as the actuators and sensors. This results in a modular control architecture since no cable connections are used between the actuators and sensors in each of the robot links. This approach increases the functionality of the mobile robot also by providing continuous rotation of each link constituting the robot.

The hybrid mobile robot's novel locomotion and manipulation capabilities were successfully experimented using a complete physical prototype. The experiments provided test results that support the hypothesis on the qualitative and quantitative performance of the mobile robot in terms of its superior mobility, manipulation, dexterity, and ability to perform very challenging tasks. The robot was tested on an obstacle course consisting of various test rigs including man-made and natural obstructions that represent the natural environments the robot is expected to operate on.